Condition:

New

Type:

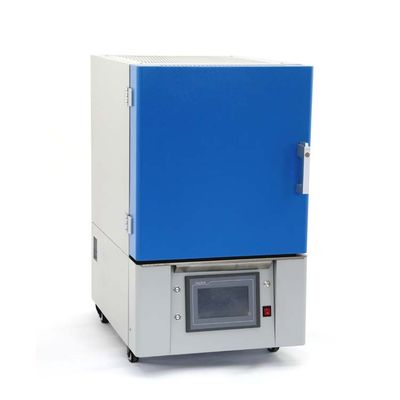

Resistance Furnace

Usage:

Heat Treatment Furnace

Video Outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

New Product 2020

Warranty Of Core Components:

1 Year

Core Components:

PLC

Voltage:

380v

Dimension(L*W*H):

12000x1000x2000

Weight (T):

5 T

Power (kW):

20

Warranty:

1 Year

Key Selling Points:

Easy To Operate

Applicable Industries:

Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Retail, Construction WorksÂ

Showroom Location:

None

Application:

Annealing Etc

Product Name:

Annealing Furnace

Furnace Type:

Continuous Production Line

Rated Voltage:

380v/50HZ/3P

Heating Element:

Resistance Wire

Ammonia Decomposition Furnace:

20m3/h

Structure:

Furnace Chamber

Power Consumption:

45kw

Output:

50kg/hour

Working Temperature:

1150.C

After-sales Service Provided:

Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Video Technical Support, Online Support

After Warranty Service:

Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Local Service Location:

None

Certification:

CE

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!