Product application scope: Graphite crucible is generally used for melting: copper, aluminum, silver, gold and other metals

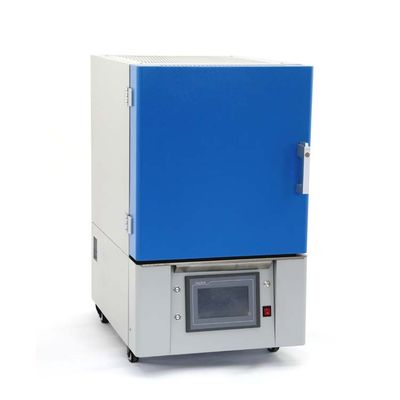

The equipment is small and light, with melting capacity ranging from a few kilograms to several hundred kilograms. There is a wide range of options, suitable for both factory production and small amounts of smelting in schools and research institutes.