Condition:

New

Type:

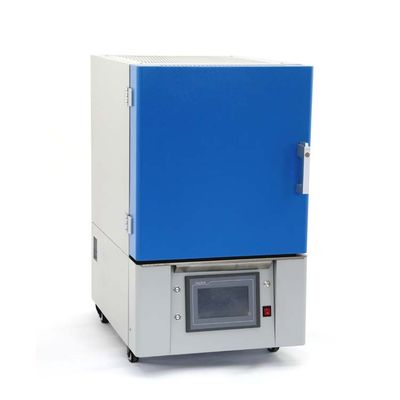

Induction Furnace

Usage:

Melting Furnace

Video Outgoing-inspection:

Provided

Machinery Test Report:

Provided

Marketing Type:

Ordinary Product

Warranty Of Core Components:

1 Year

Core Components:

Thyristor, Capacitor

Voltage:

380V

Dimension(L*W*H):

1.45M* 1.45M*1.7M

Weight (T):

3 T

Power (kW):

400

Warranty:

1 Year

Key Selling Points:

Competitive Price

Applicable Industries:

Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Retail, Construction Works , Steel Melting Foundry Plant

Showroom Location:

Egypt, Viet Nam, Indonesia, India, Russia, Thailand, South Korea, Algeria, Sri Lanka, Kazakhstan, Uzbekistan, Malaysia

Melting Material:

Three-way Catalyst

Melting Time:

50 Minutes

Power Supply:

400kw Can Be Adjusted

Input Voltage:

380V

Configuration:

Series Inverter Or Parallel Inverter

Copper Materials Brand:

Chinalco Luoyang Copper Co., Ltd

SCR Thyristor Brand:

Tech Semiconductors

Melting Temperature:

Above 1750 Degree Celsius

Power Consumption:

550KWH TO 630KWH Per Ton

Certification:

ISO9001; CE

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!